Rocking Slab Stabilization, Tucson AZ

- StraightLine Construction

- Nov 21, 2022

- 2 min read

Ram Jack Arizona was contacted by a national property management firm about some rocking slab issues their tenant was experiencing. The tenant, a global pharmaceutical equipment supplier, was having issues with the slabs rocking when their forklifts traversed the slab. And with over $500M in inventory at this location, the potential for equipment damage required the issue to be repaired quickly and with minimal disruption to the tenant. Slab settlement was the suspected culprit, and Ram Jack Arizona is adept at repairing slab settlement with polyurethane foam injection.

During an onsite inspection by Ram Jack Arizona, however, the profile of the slabs did not match the typical slab settlement. After working with the NCFI Geotechnical team, it was concluded that the rocking was due to “slab curling” rather than settlement.

What is slab curling? Per the article “Why Slabs Curl” by Bruce A. Suprenant, “Slab curling is a common occurrence that is caused by differences in moisture content between the top and bottom of the slab. The slab edges curl upward when the surface is drier and shrinks more or is cooler and contracts more than the bottom. The curl can result in loss of contact between the slab and subbase.” This observation was key to recommending the correct repair method for the owner and tenant.

The interior floor consists of adjoining 20’x 20’ individually poured slabs. Typically, when lifting a slab on grade, injections are started in the “deepest” part of the dip. In this case that would have been near the center of each 20’ x 20’ slab. Since the rocking was due to slab curling and not settlement, however, there was no dip in the middle of the slab to lift. And because of Ram Jack’s identification of the curling, they avoided the mistake of lifting in the center of the panel which would have raised the entirety of these relatively small slabs, including the edges, worsening the problem instead of fixing it.

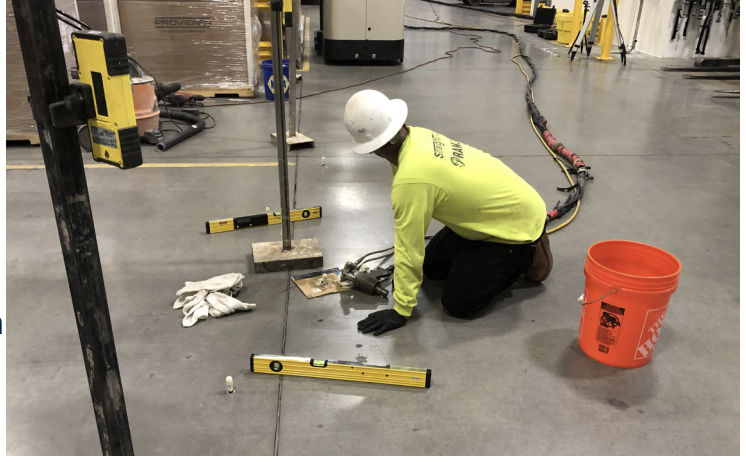

Ram Jack Arizona used NCFI TerraThane 24-003 to stabilize the joints of 47 slabs, completing the initial phase of the project in approximately 12 hours. The work was completed overnight on a weekend and did not impact ongoing operations at the warehouse. The success of Ram Jack Arizona’s solution has resulted in Phase II operations to stabilize the remaining portions of the facility.

Watch some of the work being done here: https://www.youtube.com/watch?v=MXSAFLp6LEw

Comments